Every steep-slope project hemorrhages money in ways most contractors never measure. Workers make redundant trips across treacherous pitches. Material bundles slide out of reach. Tasks that should take minutes stretch into hours. The problem isn’t just safety compliance—it’s operational efficiency bleeding profitability from every job.

The solution lies not in simply installing more roof anchors, but in fundamentally rethinking their purpose. When anchor systems are designed around workflow optimization rather than minimum code compliance, they transform from safety mandates into productivity infrastructure that crews actively demand. This shift from compliance-driven to workflow-driven placement represents the difference between anchors that slow your team down and systems that accelerate project completion.

The roofing industry faces a critical gap between fall protection engineering and productivity engineering. While existing guidance focuses on where anchors must go to satisfy regulations, it ignores where anchors should go to support actual work patterns. This disconnect creates the friction that makes crews resist safety equipment—not because they’re reckless, but because poorly positioned anchors genuinely impede their workflow.

Steep-Slope Anchor Strategy Essentials

- Hidden productivity losses from unanchored work often exceed 25-35% in labor costs and material waste

- Code-compliant anchor placement frequently misaligns with material staging zones and high-activity work areas

- Workflow analysis reveals optimal anchor positioning based on task sequences and material flow patterns

- Pre-project anchor mapping eliminates on-site decision delays that consume billable crew time

- Productivity-focused framing converts crew resistance into advocacy for anchor system adoption

Calculating the Hidden Costs of Unanchored Steep-Slope Work

The true expense of working steep slopes without proper anchor infrastructure extends far beyond obvious safety incidents. Every repositioned material bundle, every extra trip down to retrieve a dropped tool, every minute spent compensating for unstable footing compounds into measurable financial drain. These micro-inefficiencies accumulate across projects, creating profit leakage that contractors attribute to “the nature of steep work” rather than identifying as a solvable operational problem.

Time studies reveal the multiplication effect clearly. A worker on a walkable 4/12 pitch can stage materials, move freely, and maintain consistent productivity throughout the day. That same worker on an unanchored 10/12 slope spends 40% more time on identical tasks—not because they’re less skilled, but because physics and instability force compensatory movements. They brace themselves with one hand. They take smaller steps. They mentally calculate every weight shift. This cognitive and physical overhead taxes every action.

The market reflects this operational challenge. The steep slope roofing materials market forecasted to reach $18.1 billion by 2030 represents massive project volume where these inefficiencies compound. Even a 5% productivity improvement across that market segment translates to hundreds of millions in recoverable labor costs. Individual contractors can capture this value by quantifying their current waste and implementing measurement frameworks.

Material damage represents another hidden cost vector. Shingle bundles placed on steep surfaces without secure staging points don’t always slide catastrophically—sometimes they just shift slightly, breaking seals and compromising installation quality. Other times they slide partially, requiring workers to interrupt their current task to re-secure materials before continuing. Each interruption breaks workflow rhythm and extends project timelines.

The visual evidence of this waste often goes unrecognized until someone quantifies it systematically. Damaged materials, interrupted workflows, and compensatory movements become so normalized that crews stop seeing them as preventable costs.

These scattered materials represent more than aesthetic disorder—they’re physical evidence of workflow breakdown. When bundles lack stable staging zones within safe reach of anchor points, materials slide, packages tear, and workers waste time managing chaos instead of progressing through installation sequences. The cost isn’t just replacement materials; it’s the compounding delay as workers address problems that proper anchor positioning would have prevented.

Labor cost multiplication manifests most dramatically on projects where pitch exceeds walkable thresholds. The following data quantifies how slope angle correlates with installation time and overall project cost:

| Roof Slope | Installation Time | Additional Requirements | Cost Impact |

|---|---|---|---|

| 3/12 to 8/12 (Walkable) | Standard | None | Base rate |

| 9/12 to 12/12 | +25% slower | Extra nails per shingle | +15-20% labor cost |

| Above 12/12 | +40% slower | Scaffolding/rigging required | +25-35% total cost |

These multipliers don’t account for the additional time savings available through strategic anchor placement. They represent the baseline cost penalty of steep work—meaning contractors who optimize anchor systems can recover significant portions of this overhead while competitors accept it as unavoidable.

Five-Star Contractors Optimize Workflow Timing to Increase Revenue

Survey of hundreds of roofers revealed that high-performing companies take 1-3 months to move leads through production workflows, achieving five-star ratings through systematic efficiency rather than speed alone. Key finding: workflow optimization and clear expectation-setting correlate directly with business ratings and revenue growth. The contractors who measure and refine their operational sequences—including anchor deployment strategies—consistently outperform those who treat each project as a unique challenge requiring on-site problem-solving.

The cascade effect multiplies individual inefficiencies. One material slippage event doesn’t just cost the time to retrieve or replace that item. It interrupts the worker who was relying on that material. It creates a decision point about whether to pause and address it immediately or continue with a suboptimal workflow. It potentially exposes the crew to safety risks if they adapt by working without proper materials in reach. These secondary and tertiary impacts transform a five-minute material retrieval into a thirty-minute project delay when all downstream effects are measured.

Diagnosing Why Standard Anchor Placement Fails Your Workflow

Most anchor installations follow a compliance-first methodology. Engineers calculate fall arrest zones, identify required coverage areas, and position anchors to satisfy regulatory minimums. This approach produces systems that protect workers in worst-case fall scenarios but often fail to support actual work activities. The fundamental problem: fall protection zones and work activity zones rarely align.

The roofing industry operates in a high-risk environment, with fatality rates near 60 deaths per 100,000 workers in 2024, demanding serious attention to fall protection. Yet this legitimate safety imperative has created an unintended consequence—anchor systems designed purely for emergency fall arrest rather than operational support. When anchors are positioned only where falls might occur, they’re frequently not positioned where work actually happens.

The static anchor problem exemplifies this disconnect. Traditional installations place permanent anchor points at fixed locations calculated for maximum fall protection coverage. But work progresses dynamically across the roof deck in predictable sequences—tear-off moves from one zone to another, decking follows behind, shingle installation proceeds in systematic patterns. Static anchors positioned for fall zones create reach limitations that force workers to stretch beyond comfortable working distances or make frequent tie-off changes that consume productive time.

Material staging represents another critical failure point. Code-compliant anchor placement considers where workers might fall, not where materials need to be positioned for efficient access. The result: staging zones end up beyond safe reach of anchor points, forcing crews to choose between securing themselves in suboptimal locations or working unsecured while accessing materials. This impossible choice—comply with safety requirements or maintain workflow efficiency—drives the crew resistance that contractors struggle to overcome.

Industry experts note the need for better integration among technologies to streamline operations. While advanced tools exist, contractors struggle with implementation that actually enhances rather than complicates workflow efficiency, particularly in safety equipment deployment.

– Industry Analysis, Roofing Contractor Magazine

This observation captures the core problem: safety equipment designed without workflow integration creates implementation friction. Anchors become something crews work around rather than tools they work with. The compliance-focused approach treats anchor systems as necessary burdens rather than productivity infrastructure.

Generic placement patterns compound these issues. Many contractors adopt standardized anchor configurations—perimeter points plus a center ridge anchor, for example—regardless of specific project characteristics. These cookie-cutter solutions ignore roof geometry variations, material staging requirements for particular products, and the sequence-specific needs of different work phases. A tear-off crew needs different anchor support than a shingle installation team, yet generic placements treat all activities as equivalent.

The following framework identifies where standard anchor approaches create workflow disruption:

Common Workflow Disruption Points From Poor Anchor Positioning

- Identify high-traffic zones where workers repeatedly travel across the roof deck

- Map material staging areas that are currently beyond safe anchor reach

- Document time lost to repositioning safety equipment during phase transitions

- Calculate worker fatigue from unnecessary movements around fixed anchor points

- Assess reach limitations forcing inefficient work sequences

Each disruption point represents recoverable productivity. High-traffic zones without convenient anchor access force workers to either disconnect and reconnect repeatedly or maintain tension on their lanyards that restricts movement. Material staging beyond anchor reach creates the choose-safety-or-efficiency dilemma. Phase transitions requiring anchor repositioning consume setup time between productive work periods. Unnecessary movements around poorly placed anchors increase physical fatigue that compounds throughout the workday. Reach limitations force workers to adapt their natural work sequence to accommodate anchor positions rather than the reverse.

The fundamental disconnect between fall arrest engineering and productivity engineering stems from divergent design objectives. Fall protection engineers ask “where might workers fall and how do we arrest that fall safely?” Productivity engineers ask “where do workers need stability during peak task load and how do we provide that support efficiently?” These questions yield different anchor placement solutions. The industry has prioritized the former while neglecting the latter, creating systems that satisfy regulations but frustrate crews.

Mapping Anchor Systems to Work Sequence and Material Flow

Workflow analysis provides the foundation for anchor placement that supports rather than impedes productivity. This methodology reverses the traditional approach—instead of positioning anchors based on theoretical fall zones and then forcing work to adapt, it maps actual work patterns and positions anchors to support those patterns while maintaining comprehensive fall protection.

The analysis begins by documenting task-specific requirements across project phases. Tear-off crews need anchor support in different zones than decking teams. Shingle installation requires material staging at specific intervals based on bundle coverage areas. Valley and ridge work demand anchors positioned at transition points where roof geometry creates both fall hazards and material handling challenges. By mapping these phase-specific needs, contractors can design anchor layouts that adapt as work progresses rather than remaining static throughout the project.

Material flow patterns reveal optimal staging zones. Shingle bundles have predictable coverage areas—typically 33 square feet per bundle for standard three-tab shingles. Workers maintain peak efficiency when they can access 3-4 bundles without moving their tie-off point. This defines a radius of productive reach around each anchor. Strategic placement positions anchors so these productive reach zones cover the entire work area with minimal overlap, eliminating dead zones where workers must stretch beyond comfortable distance or make unnecessary tie-off changes.

Systematic workflow optimization yields measurable improvements. Similar to how successful approaches to design and build projects require integrated planning from the outset, anchor system design benefits from front-end analysis rather than on-site improvisation. The following data quantifies the productivity gains available through this methodology:

| Metric | Before Optimization | After Workflow Mapping | Improvement |

|---|---|---|---|

| Administrative Time | 40 hours/month | 30 hours/month | 25% reduction |

| Material Handling Time | 3.5 hours/1000 sq ft | 2.6 hours/1000 sq ft | 26% faster |

| Worker Movement Efficiency | 65% | 82% | +17 percentage points |

These improvements stem from eliminating the micro-inefficiencies that standard anchor placement creates. Reduced administrative time reflects less on-site decision-making about anchor positioning. Faster material handling results from staging zones positioned within optimal anchor reach. Movement efficiency gains come from anchor placement that supports natural work progression rather than forcing workers to adapt their movements to arbitrary anchor locations.

Roof geometry and physics identify critical anchor positions that code-compliant approaches often miss. Slope transition points—where pitch angle changes—create both fall hazards and material slippage zones. Valleys concentrate water flow during installation and create awkward working angles. High-traffic corridors where workers repeatedly traverse the deck benefit from continuous anchor coverage rather than isolated points. These geometry-driven considerations produce anchor layouts that address real operational challenges rather than theoretical fall scenarios.

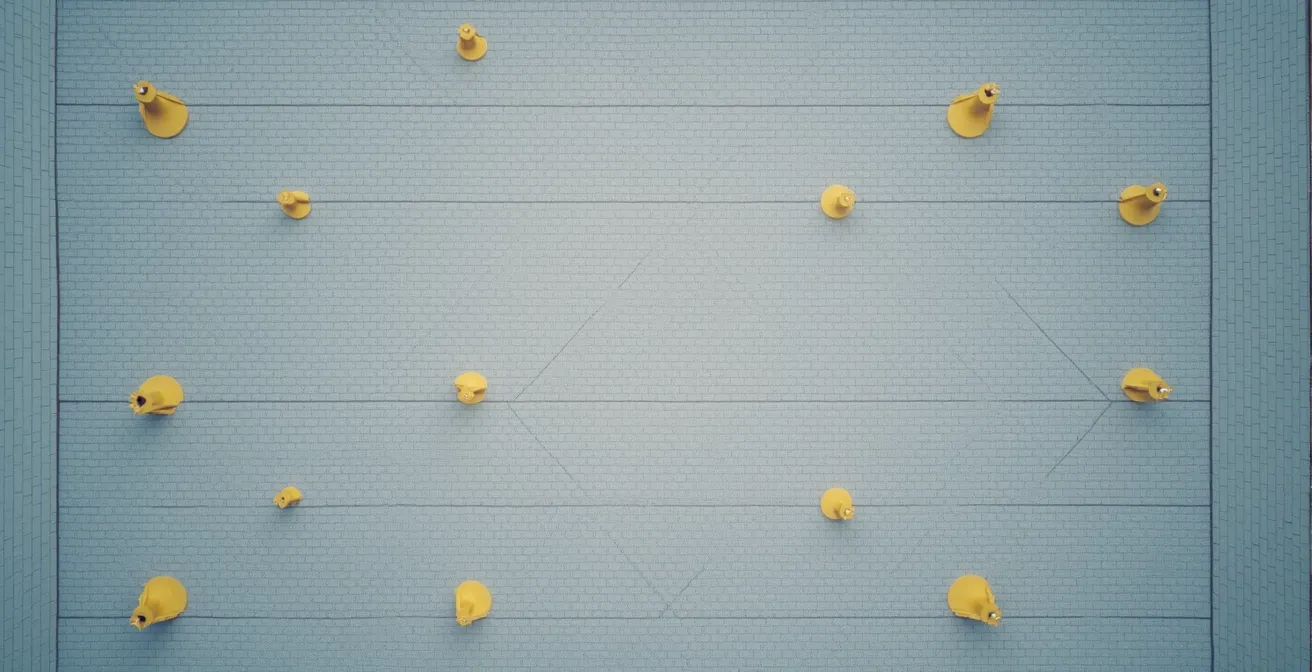

Visualizing optimized anchor placement reveals the strategic logic that separates workflow-driven systems from compliance-minimum installations.

The systematic grid pattern visible from this perspective demonstrates how workflow-optimized anchors create predictable support zones across the entire work surface. Rather than isolated points that leave coverage gaps, strategic placement ensures workers remain within productive reach of secure anchor points regardless of their position on the deck. The spacing reflects actual material bundle coverage areas and task-specific movement patterns rather than arbitrary geometric divisions.

CRM systems allow contractors to track customer inquiries, schedule appointments, and automate tasks while optimizing workflow strategies.

– Leap Digital Platform Report, 10 Best Roofing Technology Trends

This technological integration principle applies equally to anchor system planning. Digital tools enable pre-project mapping that was previously impractical. Contractors can model anchor layouts against specific project parameters, test different configurations, and arrive on-site with a proven deployment plan rather than improvising placement decisions under time pressure.

Task-specific anchor configurations adapt to different work requirements. Tear-off phases benefit from perimeter-focused anchors that allow interior material removal without constant repositioning. Deck work requires coverage that supports systematic progression across the surface. Shingle installation demands material staging integration with anchor positioning. Rather than deploying a single static configuration, workflow-driven systems anticipate these varying needs and provide adaptable support throughout the project lifecycle.

Eliminating Setup Delays Through Strategic Anchor Configuration

The primary objection preventing anchor system adoption remains consistent across crews: “anchors slow us down.” This resistance stems from legitimate experience with poorly implemented systems that do create setup delays. The solution isn’t to dismiss crew concerns but to address their root cause through strategic configuration that makes anchor deployment rapid and predictable.

Pre-project anchor mapping during the estimation phase eliminates on-site decision paralysis. When site assessment includes workflow analysis and anchor positioning planning, crews arrive with a clear deployment map rather than facing “where should we put these?” questions that consume billable time. This advance planning mirrors the systematic approach required for choosing business technology—upfront analysis prevents costly mid-implementation course corrections.

The cost impact of poor anchor planning manifests clearly in steep-slope projects. Research confirms that steep roofs above 12/12 pitch cost 25-35% more than moderate slopes, with much of this premium stemming from installation complexity and safety equipment requirements. Strategic anchor configuration can recover a significant portion of this cost penalty by transforming anchors from time-consuming obstacles into efficiency enablers.

Rapid-deployment anchor systems reduce setup time from hours to minutes through design features that prioritize ease of installation. Temporary anchor points with tool-free attachment mechanisms eliminate the fumbling with wrenches and adjustment that characterizes older systems. Color-coded components prevent assembly errors. Standardized connection points ensure compatibility across different roof types. These design considerations transform anchor setup from a skilled task requiring problem-solving into a streamlined process that crew members can execute quickly and consistently.

Template-based configurations for common roof geometries provide ready-made solutions that eliminate analysis paralysis. Rather than treating each project as a unique anchor placement puzzle, contractors develop standardized approaches for recurring scenarios—standard gable roofs, hip roofs, complex multi-level structures. The following templates provide starting points that crews can deploy rapidly:

| Roof Type | Pitch Range | Anchor Configuration | Key Benefit |

|---|---|---|---|

| Standard Residential | 3/12 to 8/12 | Perimeter + Ridge | Basic fall protection |

| Steep Slope | 9/12 to 18/12 | Grid Pattern + Staging Zones | Material control + mobility |

| Complex Multi-Level | Mixed pitches | Transition Point Focus | Phase-specific efficiency |

These templates don’t eliminate professional judgment—contractors still adapt configurations to specific project characteristics. But they provide proven starting points that reduce setup time and ensure comprehensive coverage without extensive on-site analysis. Crews internalize these patterns, making deployment increasingly automatic with repetition.

Parallel setup protocols prevent anchor installation from consuming billable crew time. Rather than having the entire crew wait while anchors are positioned, strategic contractors have anchor systems ready before crew arrival. This might involve a foreman arriving thirty minutes early to deploy anchors based on the pre-project map, or dedicating one crew member to anchor setup while others begin preparatory tasks that don’t require fall protection. The key principle: anchor deployment happens in parallel with other setup activities rather than as a blocking prerequisite that delays productive work.

Physical evidence demonstrates how properly implemented anchor systems enhance rather than impede crew confidence and productivity.

The relaxed working posture and focused attention on the task—rather than on maintaining precarious balance—illustrates the productivity benefit of reliable anchor support. When workers trust their anchor systems and can access them without workflow disruption, safety equipment transitions from a compliance burden to a tool that enables faster, higher-quality work. The visible anchor system in this scenario isn’t central to the composition because it’s become integrated infrastructure rather than an obstacle requiring conscious navigation.

Digital contracting platforms further streamline anchor deployment by integrating planning tools with project management workflows. Mobile task management applications allow foremen to access anchor deployment maps on-site, mark completion status, and document installation for quality assurance purposes. This digital integration creates accountability while reducing the cognitive load on crew members who previously had to remember complex anchor configurations or improvise solutions in the field.

The transformation from time-consuming obstacle to streamlined infrastructure requires both better anchor system design and improved implementation processes. Hardware improvements—tool-free connections, lighter materials, color-coded components—address the equipment side. Process improvements—pre-project mapping, template configurations, parallel setup protocols—address the workflow side. Contractors who optimize both dimensions achieve the dramatic setup time reductions that convert crew skepticism into advocacy.

Transforming Safety Equipment Into Crew-Demanded Productivity Tools

Technical optimization alone doesn’t guarantee anchor system adoption. The human factor—crew psychology, resistance to change, skepticism about safety equipment—determines whether optimized systems get used consistently or circumvented when supervisors aren’t watching. Transforming this resistance into genuine buy-in requires reframing anchors from compliance mandates into productivity tools that crews actively want to use.

The industry has made significant progress in safety equipment provision. Current data shows that 83% of contractors now provide all safety equipment to workers, eliminating cost as a barrier to adoption. This near-universal equipment availability means the remaining adoption challenges are primarily behavioral and perceptual rather than financial. Crews have access to anchors; the question is whether they use them consistently and whether they perceive them as helpful or burdensome.

Productivity-first framing addresses this perceptual challenge by leading with efficiency benefits rather than safety compliance. Instead of “you must use anchors to avoid falls,” the message becomes “these anchor positions will cut your material handling time by 25% and eliminate the triple trips you’re currently making.” This reframing aligns anchor adoption with crew interests—finishing faster, working with less physical strain, going home earlier—rather than positioning it as a management-imposed constraint.

Measuring and transparently sharing before/after productivity metrics provides empirical proof that converts skeptics. When crews can see documented evidence that strategic anchor use reduced their project completion time from 4.5 days to 3.5 days, or that worker trip counts decreased by 40%, the abstract claim “anchors improve productivity” becomes concrete, verifiable reality. This transparency builds credibility and creates internal advocates who share their positive experiences with resistant peers.

Physical strain reduction and end-of-day fatigue benefits resonate powerfully with experienced crew members. Veterans who’ve spent years compensating for unstable footing on steep slopes—bracing with one hand, taking shortened steps, maintaining constant tension in their core muscles—immediately recognize the difference when proper anchor systems provide stable support. The cumulative effect of this reduced strain manifests as less end-of-day exhaustion, fewer aches and pains, and sustained energy levels throughout multi-day projects. These quality-of-life improvements often motivate adoption more effectively than safety statistics or compliance requirements.

High-revenue roofing companies are accepting more payment types and using more communication methods to accommodate customers and reduce friction.

– Peak Performance Industry Report, JobNimbus 2024 Roofing Benchmarks

This principle of friction reduction applies equally to internal crew processes. Just as successful companies reduce customer friction through operational optimization, successful anchor implementation reduces crew friction through workflow-integrated design. When anchor systems accommodate rather than impede natural work patterns, adoption becomes the path of least resistance rather than a compliance hurdle to circumvent.

Creating positive feedback loops makes continued adoption self-reinforcing rather than requiring constant enforcement. Initial implementation might require management oversight to ensure consistent use. But when crews experience tangible benefits—faster completion times, reduced physical strain, fewer material handling frustrations—they begin requesting anchor systems on subsequent projects rather than needing to be reminded. This transformation from enforced compliance to crew-demanded infrastructure represents the ultimate success metric for anchor implementation programs.

Communication strategies emphasize the material handling infrastructure framing rather than safety equipment terminology. Referring to “staging support systems” or “material control infrastructure” positions anchors as productivity tools that happen to provide fall protection, rather than fall protection equipment that might incidentally help with staging. This linguistic shift seems subtle but powerfully influences crew perception and adoption attitudes.

Peer influence accelerates adoption once early adopters demonstrate benefits. When respected crew leaders vocally advocate for anchor systems based on their productivity experience, that endorsement carries more weight than any management directive. Strategic contractors identify and cultivate these internal advocates, giving them opportunities to share their experiences and mentor resistant peers. The resulting peer-to-peer adoption dynamic proves far more effective than top-down compliance enforcement.

Key Takeaways

- Operational waste from unanchored steep-slope work compounds into 25-35% cost premiums that workflow-optimized anchor systems can largely recover

- Effective anchor placement requires workflow analysis mapping task sequences and material flow patterns rather than minimum code compliance positioning

- Pre-project anchor mapping and template configurations eliminate on-site decision delays while parallel setup protocols prevent anchor deployment from consuming billable crew time

- Productivity-first framing and transparent before/after metrics transform crew resistance into advocacy by proving tangible efficiency gains rather than emphasizing compliance requirements

Conclusion

The transformation from viewing anchors as compliance burdens to recognizing them as productivity infrastructure requires both technical optimization and cultural change. Contractors who quantify their current operational waste, diagnose why standard anchor approaches fail their specific workflows, and implement strategic placement based on work sequence analysis gain measurable competitive advantages. The 25-35% cost premium that steep slopes impose becomes partially recoverable rather than simply accepted as unavoidable.

This productivity-driven approach to anchor systems represents a broader principle applicable across roofing operations: systematic workflow analysis identifies optimization opportunities that generic best practices miss. The same analytical methodology that reveals optimal anchor positioning can improve material procurement timing, crew scheduling efficiency, and quality control processes. Contractors who develop this workflow optimization capability compound their competitive advantages across all operational dimensions.

The path forward begins with measurement. Document current time losses, material waste, and worker movement patterns on steep-slope projects without optimized anchor support. Quantify the baseline to establish clear improvement targets. Then implement strategic anchor placement on a pilot project, measure the results, and share the documented productivity gains with crews. This evidence-based approach builds the internal credibility necessary for organization-wide adoption.

Crew buy-in ultimately determines success regardless of how well-optimized the technical anchor configuration might be. By framing anchor systems as material handling infrastructure that reduces physical strain and accelerates project completion, contractors align safety equipment with crew interests rather than positioning it as a management-imposed constraint. This alignment creates the positive feedback loops that make anchor adoption self-reinforcing and transforms safety equipment into crew-demanded productivity tools.

Frequently Asked Questions on Roofing Safety

How do productivity-focused anchor systems differ from standard safety setups?

Productivity systems position anchors based on actual work patterns and material flow rather than minimum compliance zones, reducing worker movement by up to 40% while maintaining full safety coverage.

What’s the typical ROI timeline for investing in workflow-optimized anchor configurations?

Most contractors report cost recovery within 3-5 projects through reduced labor hours and material waste, with ongoing savings of 15-25% on steep-slope installations.

How can I convince my crew that anchor systems speed up rather than slow down their work?

Track and share time-motion data showing reduced trips, document physical strain reduction, and emphasize how strategic placement eliminates material repositioning delays that actually waste the most time.